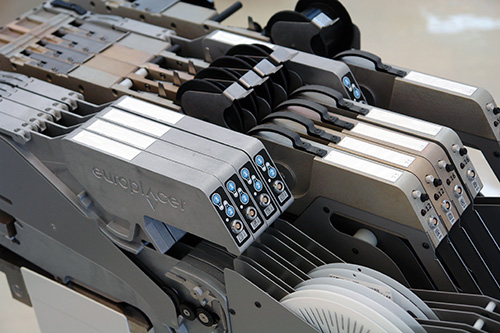

Our SMT intelligent feeders store data about the component type loaded and communicate with the machine to maximise placement efficiency and avoid faulty configuration. Capable of being programmed and replenished off-line, the machine will automatically recognise and optimise the production routing to accommodate the feeder.

If a program requires more component types than can be loaded on the machine during initial set-up, additional components can be prepared and introduced individually or by changing a complete feeder trolley.

They can be placed anywhere on the machines, there are no dedicated slots, allowing a first time right loading plan.

Each feeder is equipped with an indicator lamp to facilitate machine control, fault finding and to indicate various states of activity. The feeder can be programmed off line via a hand held micro-terminal that can read 1D and 2D bar codes, through the offline programming station software, or directly by the machine interface.

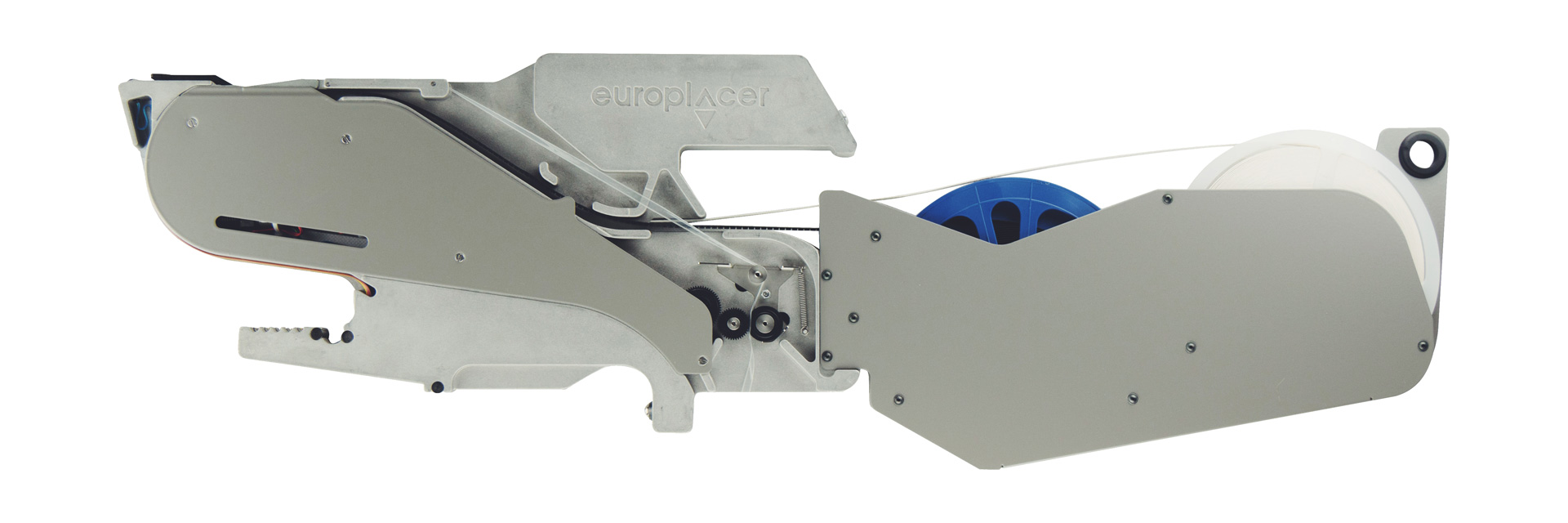

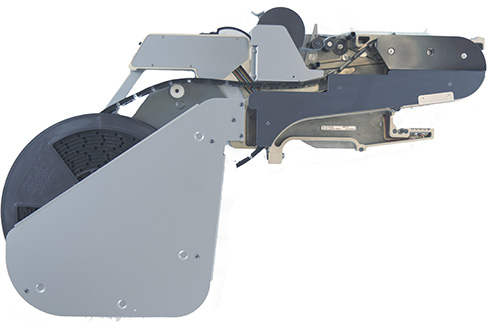

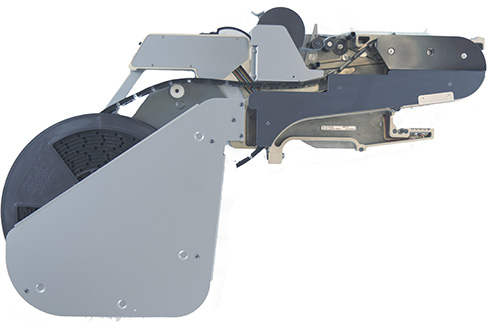

Fast and accurate calibration of the pick up position is achieved through an individual fiducial mark being present on the feeder, which is recorded when the feeder is loaded into the machine. Accuracy and flexibility of the feeder system provides a huge range of tape sizes from 4mm to 104mm and the capability to reliably place 01005 devices.

Features

SMT Intelligent Feeder 2x4mm

- Handle all tapes no matter plastic or paper

- Fed components down to 01005 chips

SMT Intelligent Feeder 2x8mm

- Handle all tapes no matter plastic or paper

- Fed components down to 01005 chips

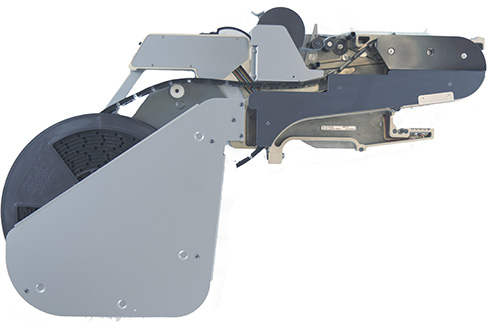

SMT Intelligent Feeder Single

- Handle all tapes no matter plastic or paper

- Feeder available for tapes between 12mm and 104mm

Request a call

Find out more about the NT intelligent SMT feeder by completing the form below to request a call back.