The long board screen printer handles boards up to 61″ (1550mm) long and 23″ (600mm) wide, ideal for LED lighting applications.

The screen printer has an accuracy of 12.5µm at 6-sigma and uses four fiducials to optimise alignment across the large board area – a factor that becomes increasingly critical with long PCBs.

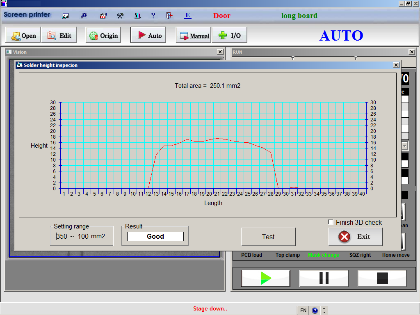

The machine also features in-built Solder Paste Inspection (SPI) technology for added process reassurance.

Features

Automation

The long board printer features laser-guided manual support pin positioning as standard, and fully automatic tooling pin placement as an option.

Stencil Cleaning

The long board printer deploys an inventive under-stencil cleaning system that operates in the X-axis to minimise the usage of cleaning consumables.

Laser Tooling

The laser tooling option is an invaluable aid to quickly and accurately position magnetic support pins in the correct locations for double sided PCBs.

Built-in SPI

SPI technology is built in to the long board machines, giving on-board 2D inspection capability for paste presence and bridge detection.

3D Solder Paste Check

This feature will check if there is enough solder paste to print the next job and will warn you in case you need to add some.

Technical Data

| EP850 | EP1220 | EP1550 | |

|---|---|---|---|

| PCB Size: in (“) mm |

33″ x 21″ 850mm x 550mm |

48″ x 23″ 1220mm x 600mm |

61″ x 23″ 1550mm x 600mm |

| Cycle Time | 11s | 14s | 16s |

| Accuracy | +/-12.5µm @ 6-sigma |

+/-12.5µm @ 6-sigma |

+/-12.5µm @ 6-sigma |

| Product Changeover | 2min | 2min | 2min |

| Product Setup | 5min | 5min | 5min |

| 2D SPI | Yes | Yes | Yes |

| Stencil Cleaning | wet/dry/vacuum | wet/dry/vacuum | wet/dry/vacuum |

| Closed loop squeegee pressure control | Yes | Yes | Yes |

Options/Accessories

Add-on modules

Laser Tooling

Find out more about our range of long board screen printers by requesting a call back.