Precision Meets Speed: Aurora Boardworks Invest for Next-Level PCB Assembly

Published: October 16, 2024

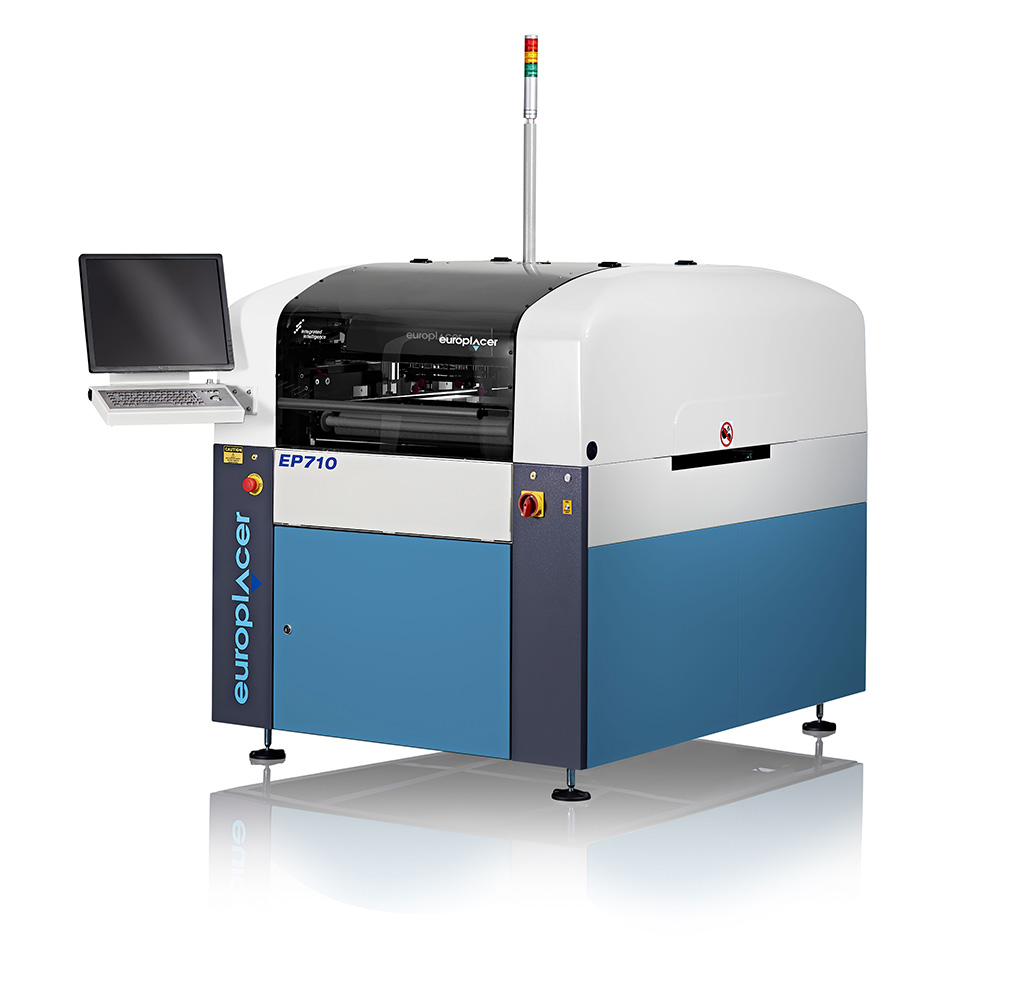

Aurora Boardworks, a prominent electronics manufacturer known for its custom-built circuit assemblies for diverse sectors, has taken a significant leap forward by incorporating two iineo 2 pick and place machines and an EP710 screen printer into their production line. This strategic enhancement has dramatically uplifted Aurora Boardworks’ manufacturing capabilities, aligning perfectly with their commitment to delivering excellence in industrial, medical, military, agriculture, oil, and gas applications.

The decision to opt for our solutions was driven by Aurora Boardworks’ need for cutting-edge technology that could offer flexibility, precision, and efficiency.

Our flagship pick and place machine, the iineo 2 is renowned for its versatility and robust performance, paired with the precision of the EP710 screen printer, made it an ideal PCB assembly set up for Aurora Boardworks. An additional advantage is the five-year warranty we offer on our equipment, which is a testament to its robustness.

Chris Merow, Director of Sales at Europlacer Americas, emphasized the synergy: “Europlacer’s technology is designed to empower manufacturers like Aurora Boardworks with the ability to scale, innovate, and lead in their industries. Our iineo 2 machines, known for their reliability and dynamic configuration capabilities, are a perfect fit for companies aiming to enhance their competitive edge.”

The integration of the iineo 2 pick and place machines has enabled Aurora Boardworks to diversify their manufacturing processes, handling more complex designs and varied component types with unprecedented accuracy and speed. The EP710 screen printer complements this by ensuring high-quality solder paste printing, critical for maintaining high standards in PCB assembly.

Daniel Stanphill, SMT Process Engineer at Aurora Boardworks, shared his insights: “When I was researching new equipment and came across Europlacer, I could not wait to bring the presentation to the whole team. I was initially only looking for a pick and place, but once we saw the capabilities of the EP710 screen printer it was impossible to pass up. Partnering with Europlacer for our SMT production needs has completely transformed our processes. We used to have to hand place a number of components, but the flexibility of the iineo platform has allowed us to virtually eliminate any hand placing. Greater quality while also reducing the average lead time for our customers- that is a win/win for everybody!”

Daniel further elaborated on the operational efficiency brought by the EP710 screen printer, “The quick and easy changeovers with the EP710 are game-changing. You unload the current stencil, change programs, set the rail width, load the new stencil, do a test alignment, load your squeegees and paste, and hit start. It’s that straightforward, which tremendously cuts down on setup time and enhances our agility.”

Aurora Boardworks’ investment in our PCB assembly technology has not only streamlined their own processes but has also brought substantial benefits to their customers. The precision and reliability of the equipment ensure that each PCB assembly meets stringent quality standards, which is crucial for applications in sensitive industries like medical and military.

The ability to quickly switch between product runs without sacrificing quality has allowed Aurora Boardworks to reduce lead times and respond more effectively to customer needs. This flexibility is particularly beneficial for clients requiring high-mix, low-volume production capabilities.

With these technological enhancements, Aurora Boardworks is well-positioned to continue its growth and expand its services. The partnership with Europlacer is a testament to Aurora’s forward-thinking approach and dedication to adopting industry-leading technologies that not only meet but exceed their clients’ expectations.

For further information on how Aurora Boardworks is advancing its PCB assembly capabilities, visit www.AuroraBoardworks.com