Level-Up Your Line

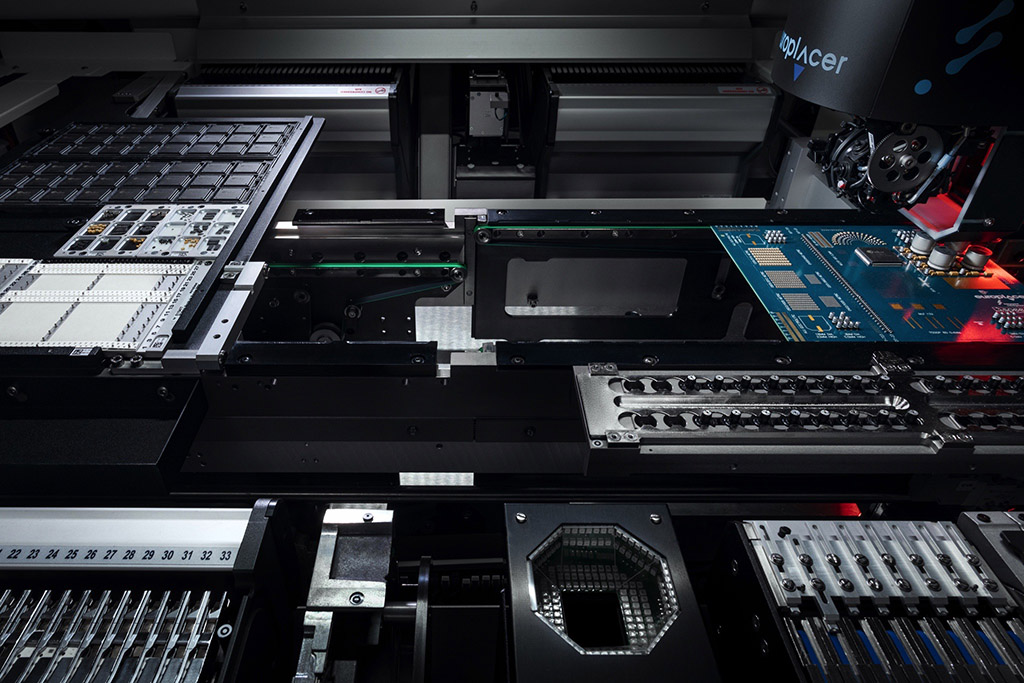

The capability of the ii-A range in a compact space where the modularity enables you to build your line with speeds up to 50,000 components per hour.

With placement speeds up to 50,000cph, the ii-A2 levels up the line by providing a resource that optimizes the placement process while maximizing the performance and throughput of Europlacer machines downstream. It has a feeder capacity of 162 x 8mm positions and handles components from 01005 profiles to 13mm x 13mm x 7mm dimensions – all in a compact module footprint.

The high speed SMT modular placement system ii-A2 is designed to deliver fast, fully intelligent and highly integrated productivity. ii-A2 is fully compatible with all relevant atom platform innovations and options, and with all Europlacer intelligent feeder technologies. It features Europlacer’s patented intelligent conveyor with board stops under full software control. Despite the compact module format, ii-A2 can handle boards up to one meter (39 inches) in length.

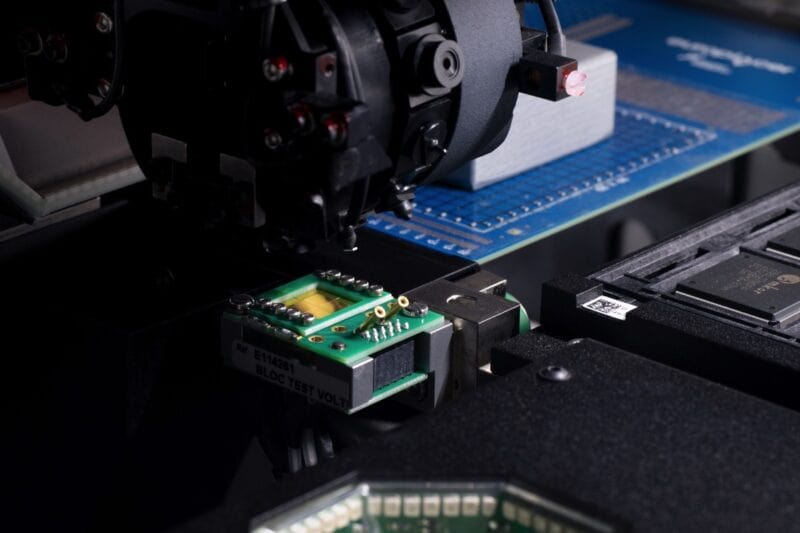

The latest intelligent technology to ensure component identification, correct pick-up, inventory management and avoid manufacturing errors.

As the original creator of intelligent feeders, you can be sure you are getting the best.

We design our platforms around the feeders to deliver an incomparably integrated pick and place solution.

The latest intelligent technology to ensure component identification, correct pick-up, inventory management and avoid manufacturing errors.

As the original creator of intelligent feeders, you can be sure you are getting the best.

We design our platforms around the feeders to deliver an incomparably integrated pick and place solution.

Technical Data

| Component Range | 01005 to 13mm x 13mm |

| Max Component Height | 7mm |

| Feeder: Tapes | 4mm to 104mm |

| Feeder: Capacity | 162 positions x 8mm |

| Feeder: Internal | – |

| Placement Heads | 2x Pulsar heads |

| Max PCB Size | 1070mm x 715mm |

| Max Placement Rate | 50,000cph |

| Placement Accuracy | 22um (QFPS) TO 46um (CHIPS) @ 3 Sigma |

Options / Accessories

Machine

- Fixed upward looking camera for larger and very fine pitch components

- Motorization of conveyor width adjustment

- Heavy PCB kit for conveyor (10 kgs)

- Wide pcb kit 715mm (no feeder at the rear)

- Rear operating station

Software and Programming

- Offline preparation

- Stock Management

- Full Traceability

- PROMON Software

- Keyboard

- Mouse

Feeders

- Barcode feeders

- Bulk feeders

- Ball feeders for BGAs

- Flux feeder & PoP processing

- Tray sequencer

Complete the form below to find out more about the atom ii-A2 pick and place machine.