The High-Volume Solution

The high speed placement machine ii-A4 takes Europlacer’s legendary flexibility to new heights, with speeds up to 104,000

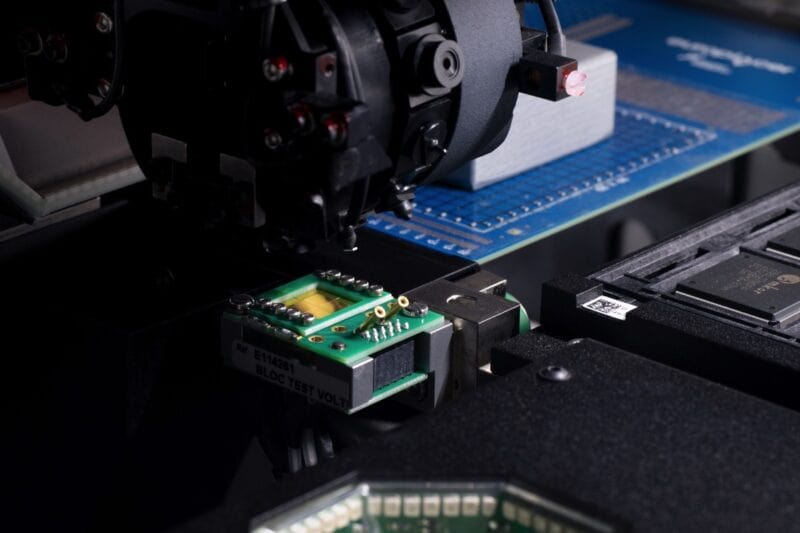

Over five years in development, the Europlacer design team set out to engineer a new platform that combines very high placement speeds with our legendary placement flexibility and accuracy. As a result, they succeeded with the high speed smt placement Atom. Therefore, now it’s possible to have a high speed AND flexible solution with no compromise. Gantries are driven in the x-axis at both ends simultaneously. They use synchronised linear motors with precision encoders. Mechanical deflection is eliminated and most importantly, acceleration is increased by 66% to 2g.

ii-A4 uses four of our advanced Pulsar Heads and offers out high speed manufacturing (up to 104,000cph). Atom is the first Europlacer platform to feature a new intelligent conveyor system. This patented technology eliminates mechanical board stops. Instead, atom machines can stop the board at any position under software control. Most importantly, it automatically optimises head travel paths during pick and place cycles and delivers another incremental step in placement performance.

The latest intelligent technology to ensure component identification, correct pick-up, inventory management and avoid manufacturing errors.

As the original creator of intelligent feeders, you can be sure you are getting the best.

We design our platforms around the feeders to deliver an incomparably integrated pick and place solution.

| ii-A4 | |

| Component Range | 01005 to 13mm x 13mm |

| (With fixed camera) | – |

| Max Component Height | 7mm |

| Feeder: Tapes | 4mm to 104mm |

| Feeder: Capacity | 264 positions x 8mm |

| Feeder: Internal | – |

| Placement Heads | 4x Pulsar heads |

| Max PCB Size | 825mm x 715mm |

| Max Placement Rate | 100,000cph |

| Placement Accuracy | 22um (QFPS) TO 50um (CHIPS) @ 3 Sigma |

- Fixed upward looking camera for larger and very fine pitch components

- Motorization of conveyor width adjustment

- Heavy PCB kit for conveyor (10 kgs)

- Wide pcb kit 715mm (no feeder at the rear)

- Rear operating station

- Offline preparation

- Stock Management

- Full Traceability

- PROMON Software

- Keyboard

- Mouse

- Barcode feeders

- Bulk feeders

- Ball feeders for BGAs

- Flux feeder & PoP processing

- Tray sequencer

Find out how the ii-A4 can revolutionize your production. Complete the form below to request a call back.