Shenzhen Ilinkglobe Technology Co Ltd – Strategic Partnership with Europlacer

Published: September 10, 2024

Shenzhen Ilinkglobe Technology Co., Ltd. was founded in 2019 and is turning 5 years in 2024. The company is engaged in the manufacturing of Surface Mount Technology with a long list of services from PCB design, assembly, and component sourcing to product assembly and aging testing. Ilinkglobe Technology is positioned as a unique solutions provider in the field of electronics manufacturing. The company offers its customers the flexibility to adopt modular services or, alternatively, complete solutions. With regards to serving its niche markets within the electronics manufacturing industry, the services it has to offer should be unique and differentiated representations of well-conceived and innovative solutions for its customers.

In its quest to serve the defined core market of high-mix, low-volume production, Ilinkglobe needed an SMT solution that was sufficiently flexible and efficient. As a company serving a variety of customers with complex needs, it was looking for a machine capable of handling a wide variety of components and delivering high quality results at different production volumes. The main challenge was to find a solution that could guarantee quality, flexibility and scalability while avoiding common manufacturing problems such as incorrect component placement and electrostatic discharge.

After extensive research and consultation, the decision to invest in Europlacer machines marked a turning point in the development of Ilinkglobe’s activities. Europlacer is one of the world’s leading SMT full-line solution providers and specialized in solutions conceived for high-mix, low-volume electronics manufacturing.

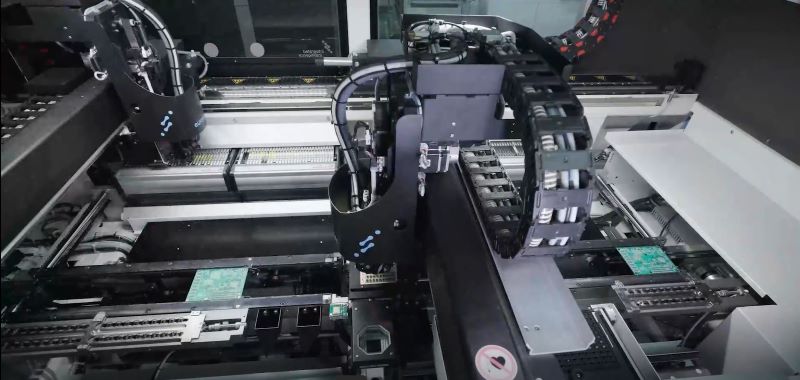

Today the Chinese company has three pick and place machines 2x iineo+I and iineo+II as well as a large range of feeders including the Freeform feeder and the automatic IC sequencer. Ilinkglobe has also invested in the Europlacer’s automatic storage system LZero3 which networks with existing MRP/ERP systems and iineo machines to efficiently pick and replenish factory orders.

Michael Wang, Ilinkglobe’s CEO stated, “At that time, when we chose Europlacer, it was based on our positioning, which focused on high-mix, low-volume production.” The decision to go with Europlacer was a result of this strategic alignment.

- Large feeder capacity: Europlacer machines have a high feeder capacity, as they can also use up to 264 slots, making it possible to use up to 400 types of components in one machine. This characteristic allowed Ilinkglobe to use a variety of components, not a small amount, easily and as a critical factor in their high mix-production environment.

- Error prevention intelligent systems: Smart systems, combined with smart trolleys of the ii-Cart and on-the-fly camera, reduce the chance of misplaced components to a great minimum. The system itself recognizes and rectifies errors automatically and ensures the maximum level of product quality without additional investment in mechanisms for protection.

- Prototyping flexibility: Prototyping often leads to handling of loose components, where Europlacer’s flexibility shone. It is in this flexible attitude that saved Ilinkglobe from a manual component placement and, in turn, better processes, raising levels of efficiency and quality, specifically when it comes to boards with complicated structures.

- Scalability and versatility: The Europlacer machines had the capability of catering to different varieties of boards, and hence, Ilinkglobe could run different orders at the same time. This simultaneous running of different orders helped in increasing their operative efficiency and smoothly scaling by this capacity.

Ilinkglobe’s decision to invest in Europlacer machines has been a wise one, as it has enabled both companies to significantly increase their revenues. Though the purchase of Europlacer machines increased the production capacities of Ilinkglobe Technology, that was not the only factor that gained experiential knowledge. As found in more than one case, the responsiveness of customer feedback by Europlacer has resulted in a firm bond and a cooperative and harmonious relationship. Over the years, the link between the two parties has developed into a close cooperation, defined as mutually beneficial and win-win.

The owner of ilinkglobe noted that the remarkable thing that distinguishes Europlacer from other European-based equipment manufacturers is the exceptional level of customer service provided. Europlacer has been kept very positive in terms of attitude to change for improvement at the customer’s behest, and as such this has also guaranteed a good lifetime service relationship.

“Our relationship with Europlacer has evolved into a very intimate partnership, continuously achieving mutual benefits and win-win outcomes,” says Michael Wang.

The partnership between Shenzhen Ilinkglobe Technology Co. and Europlacer is a perfect example of how technological collaboration can stimulate business growth. Strategic investments in innovative SMT solutions from Europlacer have enabled Ilinkglobe to maintain leadership in the high-mix, low-volume electronics manufacturing sector. Their continued collaboration seeks to bring innovation and keep their competitive edge in place, thereby ensuring that each firm benefits from the success of the other.