The Versatile Module

All the capability of the ii-A range in a compact space, modular, enabling you to build your line, with speeds up to 15,000

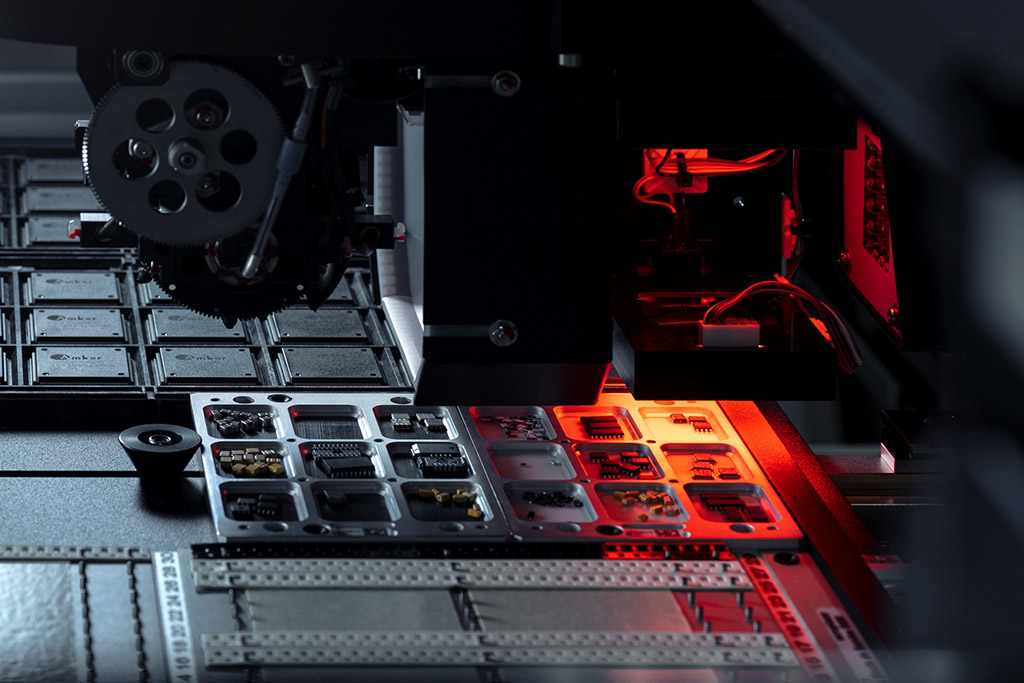

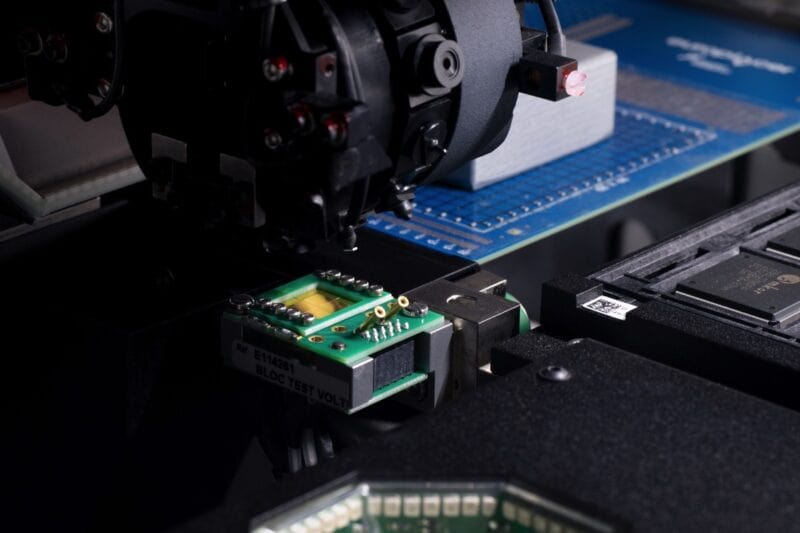

The ii-A1 multi-functional SMT placement machine delivering unparalleled flexibility across a broad range of component sizes.

The ii-A1 is a versatile machine featuring a single Tornado turret head with eight or twelve nozzles, 162 feeder positions and 2 internal matrix trays, all in a compact footprint, configurable for specific SMT assembly duties or as a fully featured stand alone module offering placement speeds up to 15,000cph.

Despite the compact module format, ii-A1 can handle boards up to 1m (39″) in length.

The latest intelligent technology to ensure component identification, correct pick-up, inventory management and avoid manufacturing errors.

As the original creator of intelligent feeders, you can be sure you are getting the best.

We design our platforms around the feeders to deliver an incomparably integrated pick and place solution.

Technical Data

| Component Range | 01005 to 50mm x 50mm |

| (With fixed camera) | 99mm x 99mm (more on demand) |

| Max Component Height | 34mm (31mm with 12 nozzles) |

| Feeder: Tapes | 4mm to 104mm |

| Feeder: Capacity | 162 positions x 8mm |

| Feeder: Internal | 2 x Matrix trays |

| Placement Heads | 1 x 8 or 12 nozzle Tornado head |

| Max PCB Size | 1070mm x 715mm |

| Max Placement Rate | 14,000cph (15,390 with 12 nozzles) |

Options / Accessories

Machine

- Fixed upward looking camera for larger and very fine pitch components

- Motorization of conveyor width adjustment

- HeavyPCB kit for conveyor (10 kgs)

- Wide pcb kit 715mm (no feeder at the rear)

- Rear operating station

Software and Programming

- Offline preparation

- Stock Management

- Full Traceability

- PROMON Software

- Keyboard

- Mouse

Feeders

- Barcode feeders

- Bulk feeders

- Ball feeders for BGAs

- Flux feeder & PoP processing

- Tray sequencer

Find out how the ii-A1 can revolutionize your production. Request a call back by completing the form below.