Brynleigh Technology strengthens longstanding partnership with Europlacer

Published: December 1, 2025

Family-run contract electronics manufacturer Brynleigh Technology Ltd has been pushing the boundaries of precision, flexibility, and innovation in electronic assembly for more than three decades. Now celebrating over 25 years of partnership with SMT pick-and-place manufacturer Europlacer, Brynleigh continues to invest in cutting-edge Europlacer platforms to meet the growing complexity and pace of customer demand.

Key Benefits:

- Placing components 35%+ faster

- Can run multiple jobs (prototypes and/or batches) on the line simultaneously due to dual setups

- Tight integration with custom in-house written software

- Now winning business back from Far East

- Customer gained confidence in equipment that has led to a partnership since 2001

A Family Business Built on Quality and Agility

Founded in a garage in the early 1990’s by Richard Apthorp’s parents, Brynleigh Technology has grown from humble beginnings into a thriving contract electronics manufacturing company (CEM) provider with a team of 30 staff.

“We’re a small CEM in East Anglia, UK,” said Managing Director Richard Apthorp. “We started out as prototyping and small batch specialists, and while we still do those jobs, as our customers have grown, we’ve evolved with them — taking on larger production volumes while maintaining our reputation for flexibility and quality.”

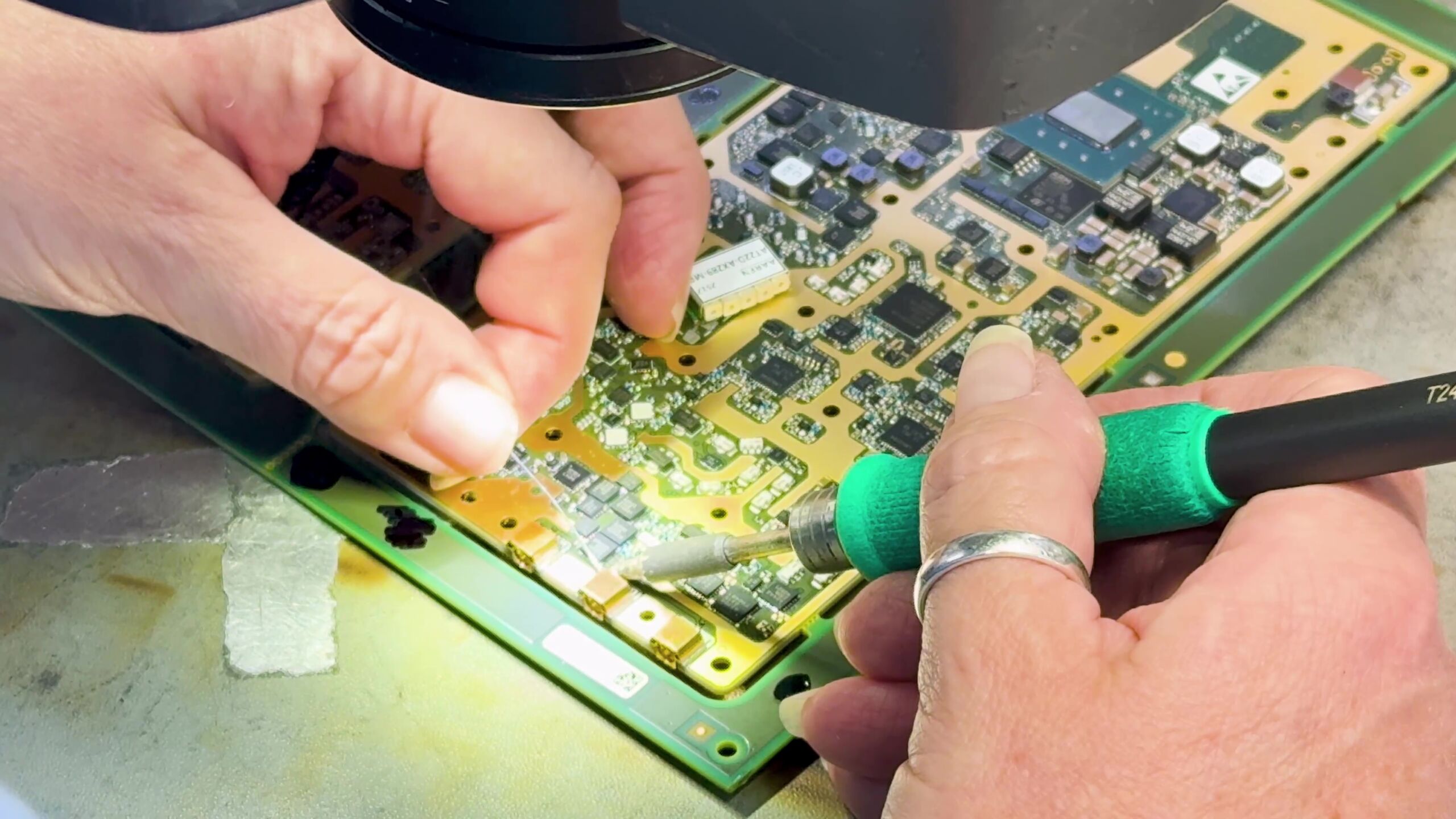

This focus on responsiveness and precision has helped Brynleigh carve out a niche in aerospace and other high-end sectors, where manufacturing defects are simply unacceptable.

“We’ve always taken on boards that others decline because they’re too difficult, giving ourselves an edge over competitors.” added Richard.

Driving Innovation Through Engineering

According to Operations Director Andy Breeze, a commitment to innovation underpins everything Brynleigh does. “We’ve never accepted the phrase, ‘that’s how we’ve always done it,’” he said. “We’re always looking at new technologies and smarter ways of working. Front-end engineering is a key focus — we simulate boards before they reach the shop floor to identify potential issues early. That’s how we maintain both speed and quality.”

This pursuit of continuous improvement extends to their choice of production equipment — an area where Europlacer has played a vital role since 2001.

A Partnership That’s Evolved Over Generations

“Our relationship with Brynleigh goes back over 20 years,” explained Elliot Loven, UK Sales Manager at Europlacer. “They’ve worked with three generations of our systems — from the Flexis, Axis, and Progress machines of the early 2000s to the iineo range, and now our latest Atom and the new iineo range platforms.”

This evolution reflects both companies’ shared philosophy of progress and adaptability.

“Speed and flexibility have always been key for us,” said Andy. “Europlacer’s systems let us place components quickly and accurately without second checks. The difference between our first single-head Finesse machine and today’s multi-head Atoms and ii-N2s is incredible. The complexity they can handle now is on another level.”

Performance, Support, and Partnership

For Brynleigh, choosing Europlacer has never just been about the technology — it’s also about trust and support.

“When you invest in capital equipment, performance is only part of the equation,” noted Elliot. “You also need confidence that the support network is there when you need it. Our UK-based service and applications teams provide that reassurance.”

Andy agreed; “Support from Europlacer has always been excellent. If we face a challenge we can message them and get an instant response. That partnership is really important to us — whether it’s with suppliers like Europlacer or with our own customers, we know that the only way to achieve great things is by working together.”

Raising the Bar in Productivity

The collaboration between Brynleigh Technology and Europlacer has delivered tangible results. “One of the key things for us is changeover times. We need to be quick, as we do a lot of jobs every day – it’s not just one big job running on the line. Europlacer’s equipment and software allow us to have the next job ready to run, so it can be just slotted on and just hit go. The size of the line, capacity of feeders and flexibility it gives us means that we can also run multiple jobs down it through dual setups. Now the new line is fully operational, we’ve seen dramatic improvements,” said Richard. “With the old line, placing 100,000 components in a day was a good result. With the new Europlacer line, we can hit that by two o’clock in the afternoon.”

The combination of productivity and precision has also helped Brynleigh attract new business — particularly from companies looking to reshore manufacturing to the UK.

“Many of our customers are bringing production back from China because of our capability and responsiveness,” added Richard. “During the pandemic, we even turned around ventilator R&D prototypes in under eight hours.” The company has built a reputation for delivering quality and reliability, both on prototyping and production runs. Noted Richard; “One customer told us that if you prototype with Brynleigh, you eliminate assembly issues — if it doesn’t work, it’s a design problem, not a manufacturing one.”

Integrated solutions

Brynleigh is unusual in that the company has in-house software development skills, allowing them to ‘join the dots’ of data communication throughout their workflow processes. Europlacer’s open software architecture allowed them to exchange all relevant data in real time, providing instant, accurate information that goes towards delivering agility and flexibility on the shop floor along with full traceability. Andy noted; “We’ve been able to combine several pieces of manufacturing equipment using our own bespoke software to make them talk to each other, and allow us to transfer data quickly and cleanly. Traceability is a very strong factor for our customers. Our systems give the ability to go back to the individual component on each board.”

Looking Ahead

With its latest Europlacer ii-A3 and ii-N2 pick and place machines, Brynleigh is well-equipped for the next chapter in its growth. Both companies continue to share a commitment to pushing boundaries and supporting the electronics manufacturing sector. “It’s been amazing to see how Europlacer has continued to innovate over the years,” said Andy. “Having the latest technology allows us to keep up with our customers’ demands.”

Curious how this could work for your business?

If your company faces similar challenges to Brynleigh Technology, why not contact us to find out how Europlacer can help you. Complete the form below to request a call back.