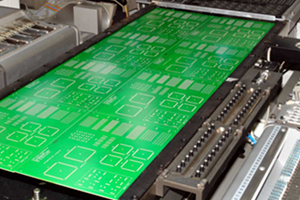

Offline AOI system specifically designed for small / medium size SMT shops, as well as being able to provide prototype inspection in large factories

Description

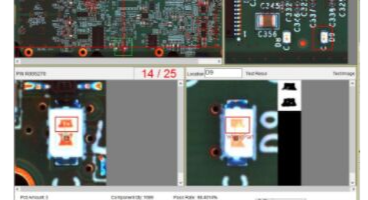

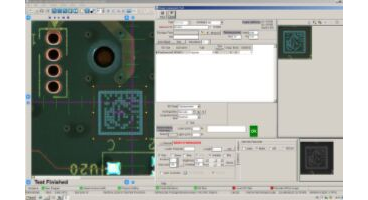

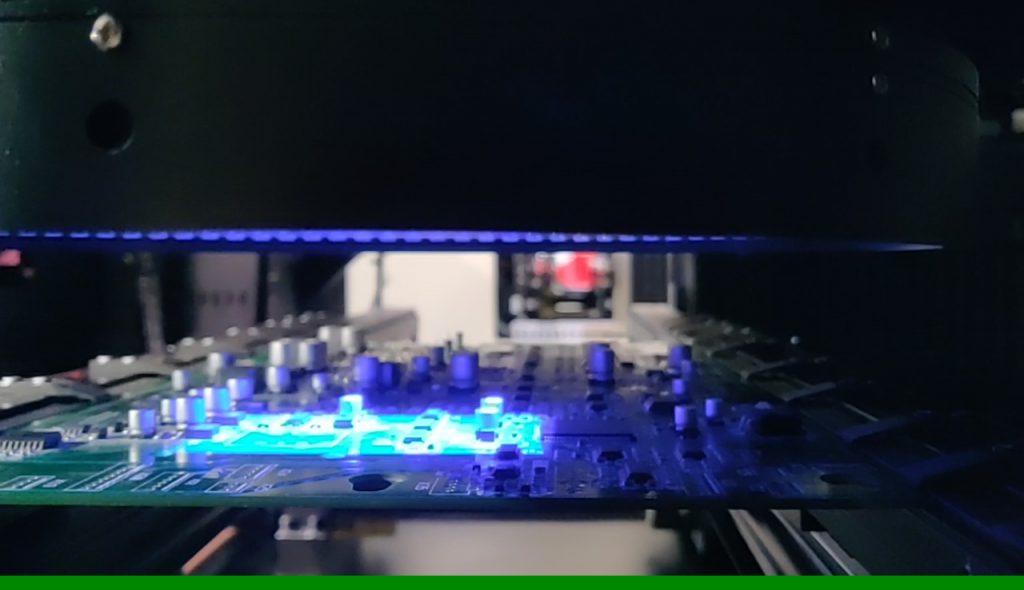

The ALD7100 Series is a high speed offline AOI system utilizing state-of-art i3D technology

powered by a high-speed camera and a multidirectional LED lighting module.

It can be used in different kinds of applications, such as TH component

inspection, glue pad contamination and more. Component marking and color inspection is part of the standard tests for all components on the board.

The ALD7100 does not require any hardware modification in order to switch between the

reflow, pre-reflow, wave or glue applications.

The machine has a small footprint, works very quietly – easily can be integrated and used in production as well as in the lab environment while delivering 100% coverage high-speed inspection with no escapes and very low false alarm rate.

Features such as integrated barcode reading, various traceability options and software process controls are also available.

Features / Benefits

High-Speed Camera

5MP High-speed Camera

LED Illumination System

Multi-directional LED illumination system

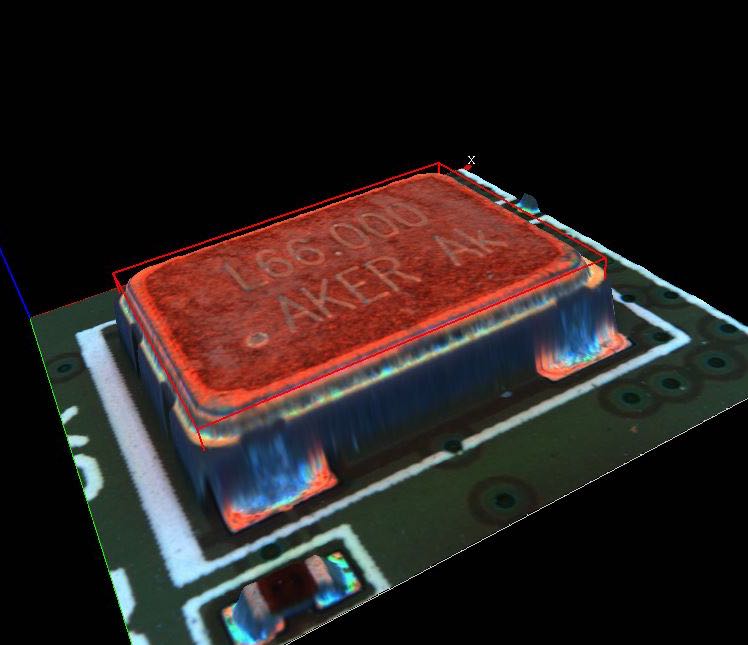

Warpage Compensation

Fully automatic warpage compensation does not require any special procedure or sample board

OCR and Colour Detection

All components inspected for colour or markings for every board. Powerful debug-free OCR algorithms

Technical Data

| ALD7100 Series | |

|---|---|

| Camera | 5MP high speed camera |

| Lighting System | Multi-directional LED lighting module |

| PCB Size | MIN 50mm x 50mm MAX 430mm x 330mm (ALD7120), 620mm x 460mm (ALD7130), 870mm x 650mm (ALD7150) |

| PCB Thickness | 0.3mm to 5mm |

| Resolution | 15µ/pixel |

| Speed | Less than 0.2 sec/FOV |

| FOV | 38.4mm x 30.9mm |

| Inspection Coverage | 100% inspection coverage, all components are inspected for all types of the defects: missing, misalignment, billboard, up-side-down, tombstone, damaged, wrong component, lifted leads, open, insufficient / excessive solder, shorts, wrong component, polarity, solder balls, etc… |

| Dimensions | 870x1060x1300 ALD7120 1060x1340x1460 ALD7130 1340x1750x1600 ALD7150 (not including signal light tower height) |

| Special Features | Supports auto-change program, multi-boards (include bad mark) and multi-program inspection modes |

Options / Accessories

Machine

- SPC

- Repair station

- Offline programming station

- External barcode scanner

- Support pins

Software and Programing

- Site Dashboard

- First Article Inspection

- Package Link