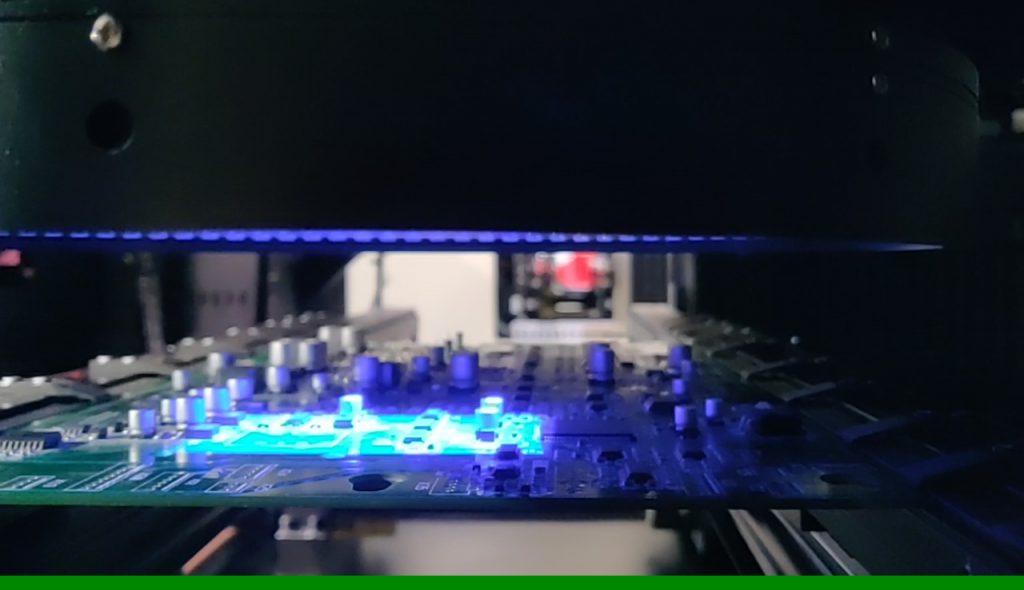

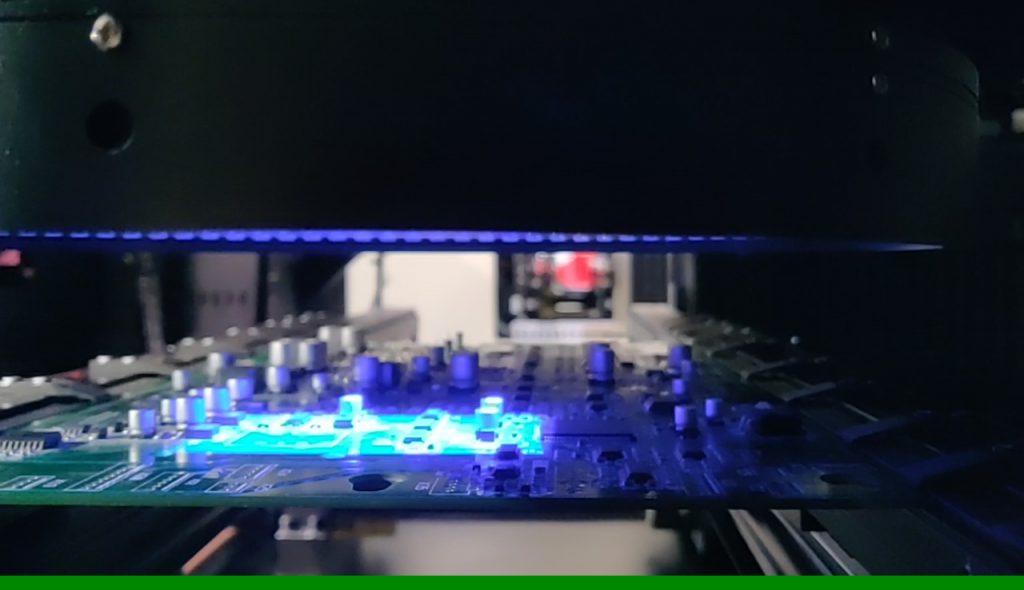

The Pre-Reflow Inline AOI accurately measures components position and supplies a feedback, which is vital to improve the performance of P&P machines. The system detects all placement defects, such as missing, misalignment, billboard, up-side-down, polarity, wrong component, lifted lead and more

In addition ALD5820S has a capability of 2D paste inspection on an assembled PCB.

Features

High-Speed Camera

4MP High-speed Camera

Extra bright RGB LED

Extra bright RGB LED – 360˚ angle and direct top light directions

Warpage Compensation

Fully automatic warpage compensation does not require any special procedure or sample board

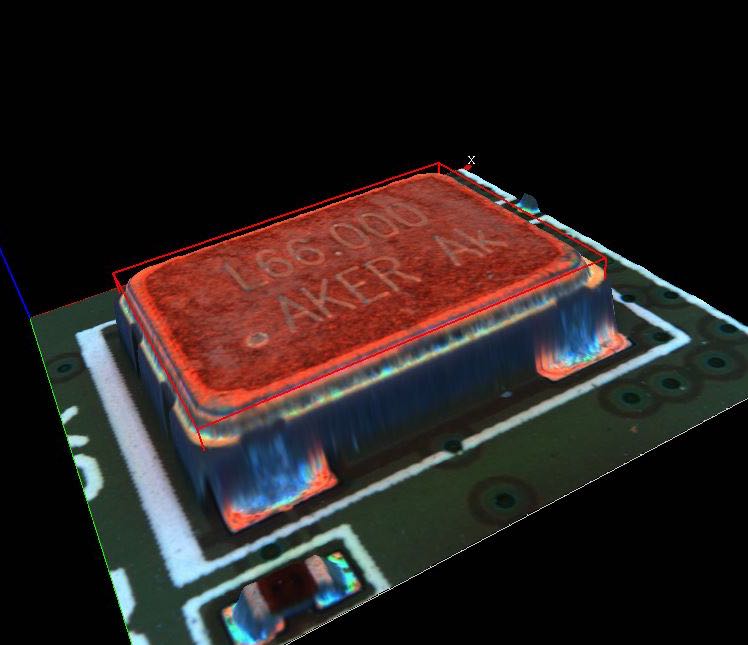

OCR and Colour Detection

All components inspected for colour or markings for every board. Powerful debug-free OCR algorithms

Technical Data

| ALD5820S | |

|---|---|

| Camera | 4MP high speed camera |

| Lighting System | Extra bright RGB LED – 360˚ angle and direct top light directions |

| PCB Size | MIN 50mm x 50mm MAX 510mm x 500mm |

| PCB Thickness | 0.3mm to 5mm |

| Resolution | Up to 8µ |

| Speed | Less than 0.17s/FOV |

| FOV | 16 x 16 mm (8µ), 30 x 30 mm (15µ) |

| Inspection Coverage | Missing, misalignment, polarity, billboard, up-side-down, damaged, wrong component, lifted leads and more 2D paste defects: insufficient solder paste, shorts, offset… |

| Dimensions | 1300x900x1565 (LxWxH) (not including signal light tower height) |

| Special Features | Supports auto-change program, multi-boards (include bad mark) and multi-program inspection modes |

Options / Accessories

Machine

- SPC

- Repair station

- Offline programming station

- External barcode scanner

- Support pins

Software and Programing

- Site Dashboard

- First Article Inspection

- Package Link

Request a call

Find out more about our pre-reflow inline AOI equipment. Complete the form below to request a call back.