With Europlacer, we can produce exactly what we need at any time, without delays or extensive reconfiguration. That has helped us dramatically reduce both production and inventory costs while staying highly competitive.

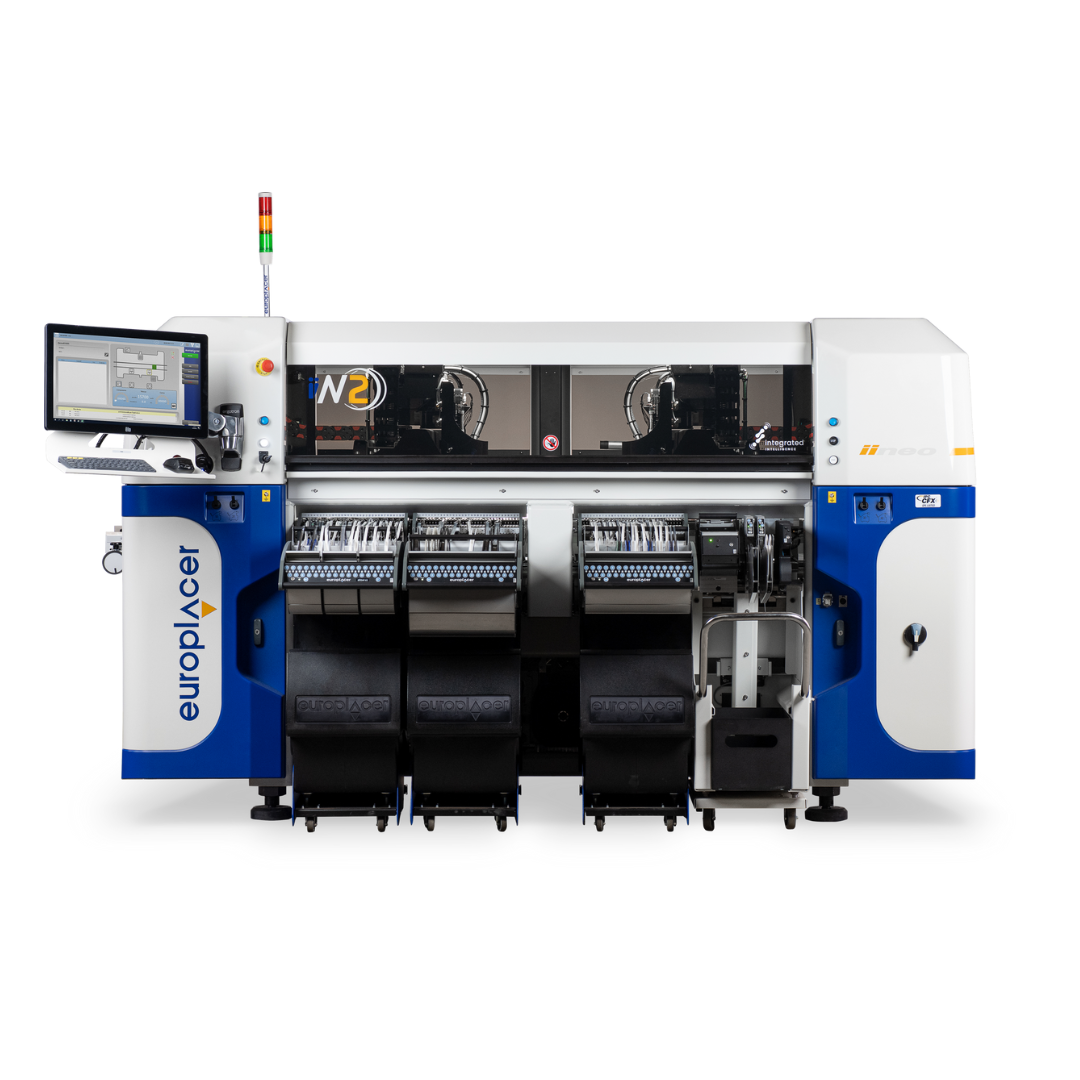

iineo range: Flexible Machines

Handle everything from prototype runs to batch production with seamless changeovers. Perfect for manufacturers who need maximum flexibility without compromising on quality or speed.

atom range: High Speed Machines

Advanced dual-gantry architecture and optimized motion paths ensure the fastest possible throughput. Built for manufacturers who measure success in units per hour and overall equipment effectiveness.

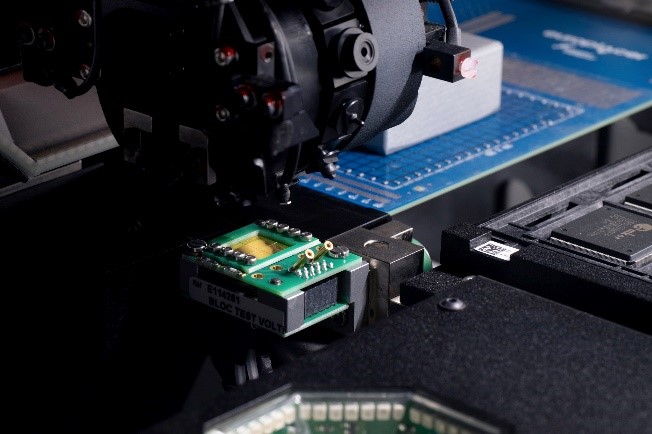

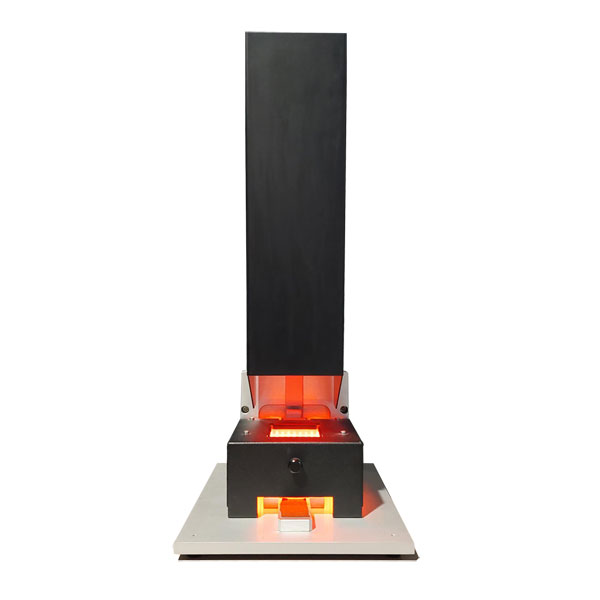

Pick and Place Accessories

Enhance and customize your Europlacer solution to match your exact requirements.

Our comprehensive range of options and accessories extends the capability of your pick and place system, from advanced testing and inspection to optimized component handling. Each addition is designed to integrate seamlessly with your machine, maximizing efficiency and expanding your production possibilities.

Use this form to request more information about our range of SMT Pick and Place machines.