EPiiCENTRE centralizes shop-floor information and turns it into clear, actionable insights, providing the visibility needed to manage production with confidence.

By combining real-time monitoring with performance analysis, EPiiCENTRE helps teams adapt quickly, optimize each production run, and drive continuous improvement, turning high-mix complexity into a sustainable competitive advantage.

EPiiCENTRE positions itself as a central tool for continuous

improvement, turning production experience from run

to run into sustainable performance gains. It fosters

a culture where each production cycle contributes to

improving the next, transforming the complexity of the

production into a true competitive advantage.

Key benefits

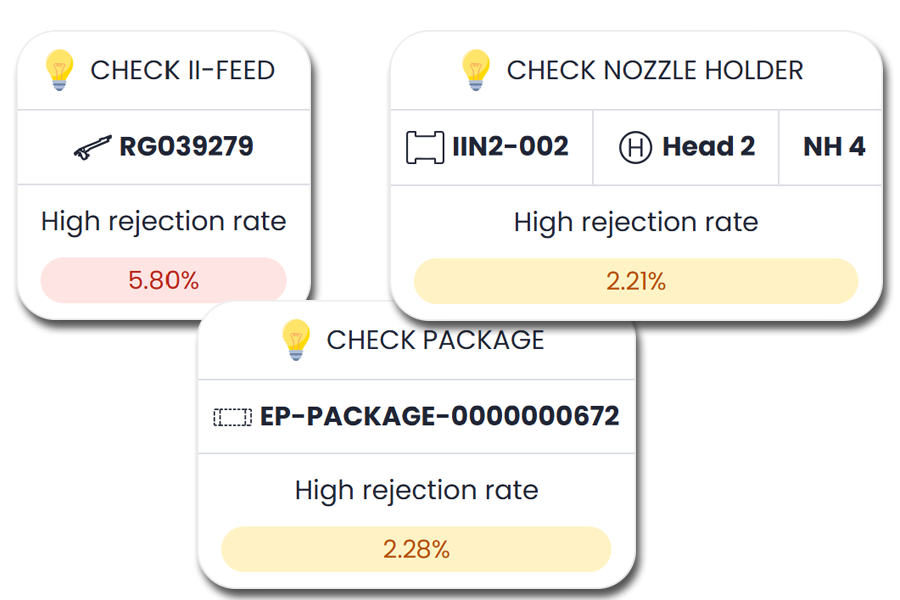

- Real-time line monitoring and prioritized attention points

- Native IPC-CFX interoperability

- Browser-based access — no client installation

- Large-screen, tablet, and smartphone compatibility

Line Monitoring

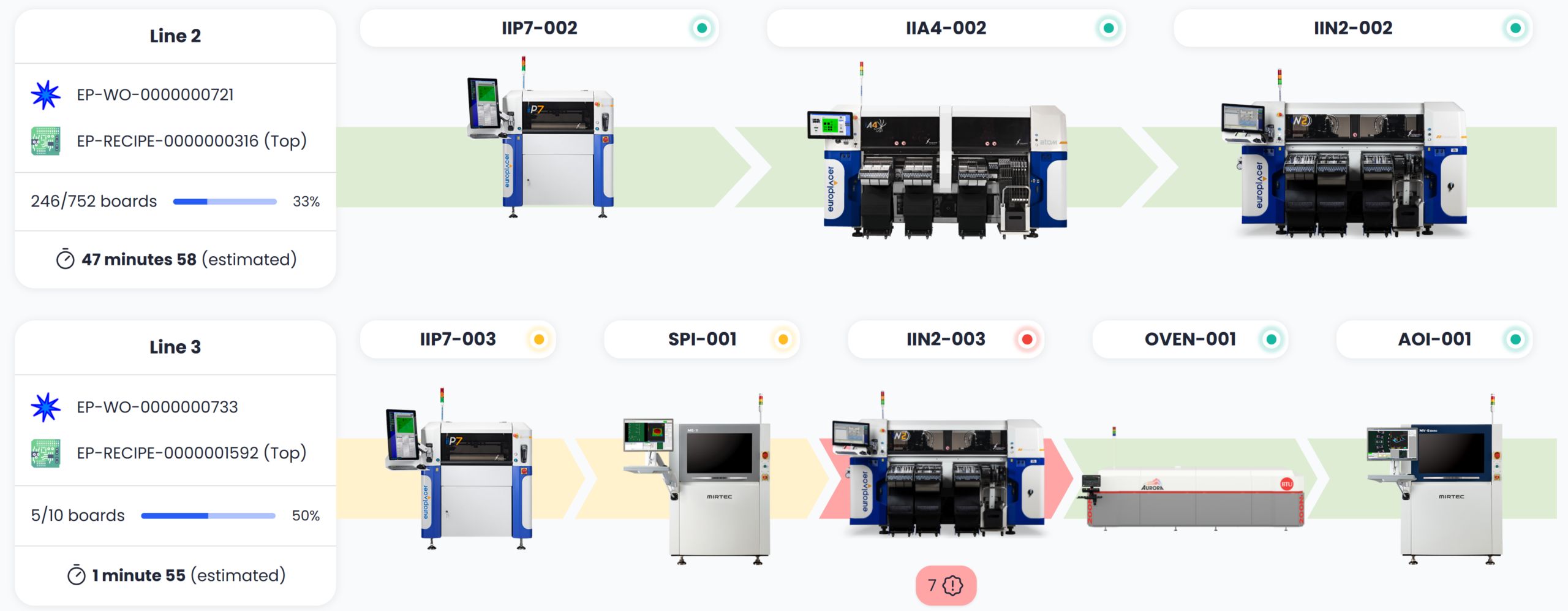

View an instant understanding of production, from factory level down to individual lines. The Factory Line view delivers an overall snapshot of all production lines and active work orders, allowing teams to quickly grasp the global situation.

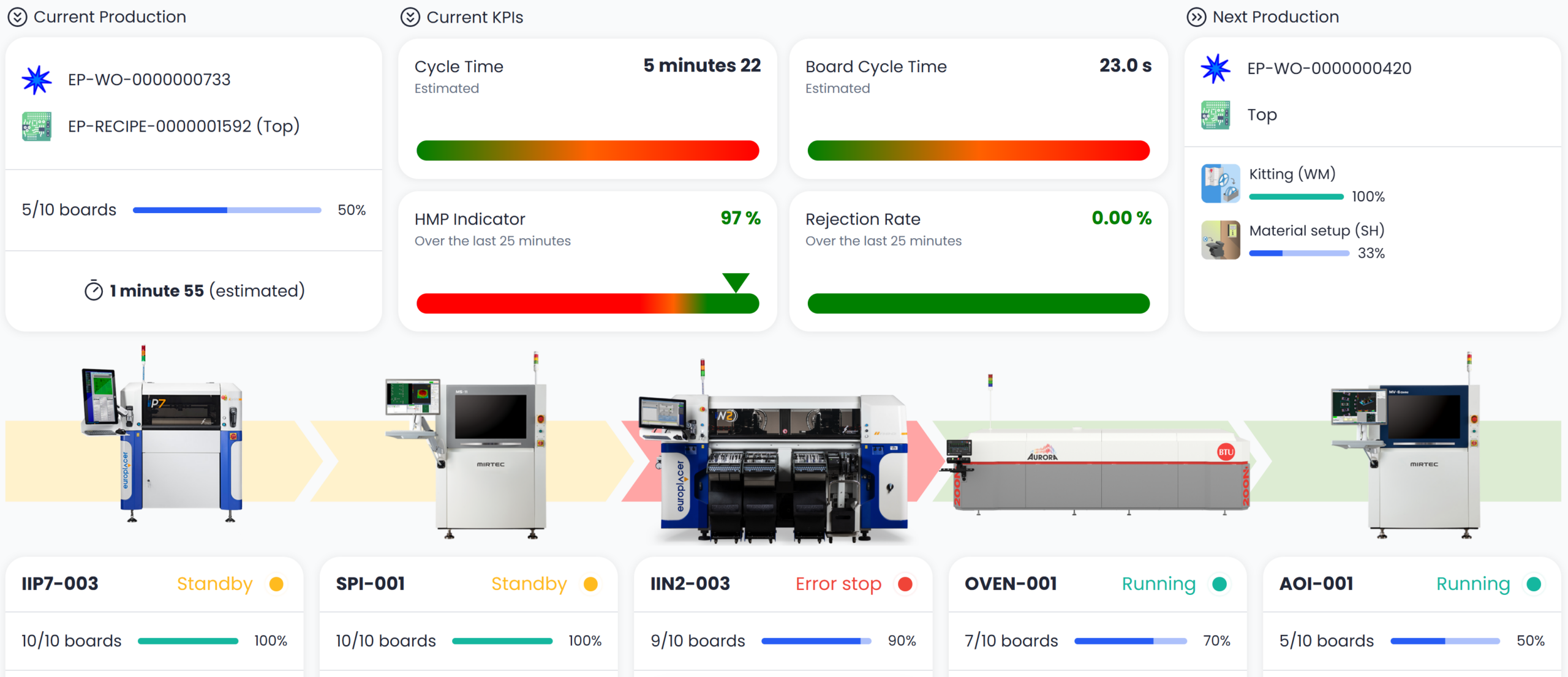

The Line Monitoring view then allows users to focus on a specific line to access more detailed information, key indicators, and attention points. This smooth navigation between high-level visibility and operational detail improves team coordination and accelerates decision-making.

By combining global insight with shop-floor precision, EPiiCENTRE helps maintain a responsive, well-controlled, and efficient production flow, even in the most demanding industries.

Line Analysis

Turn performance data into insight

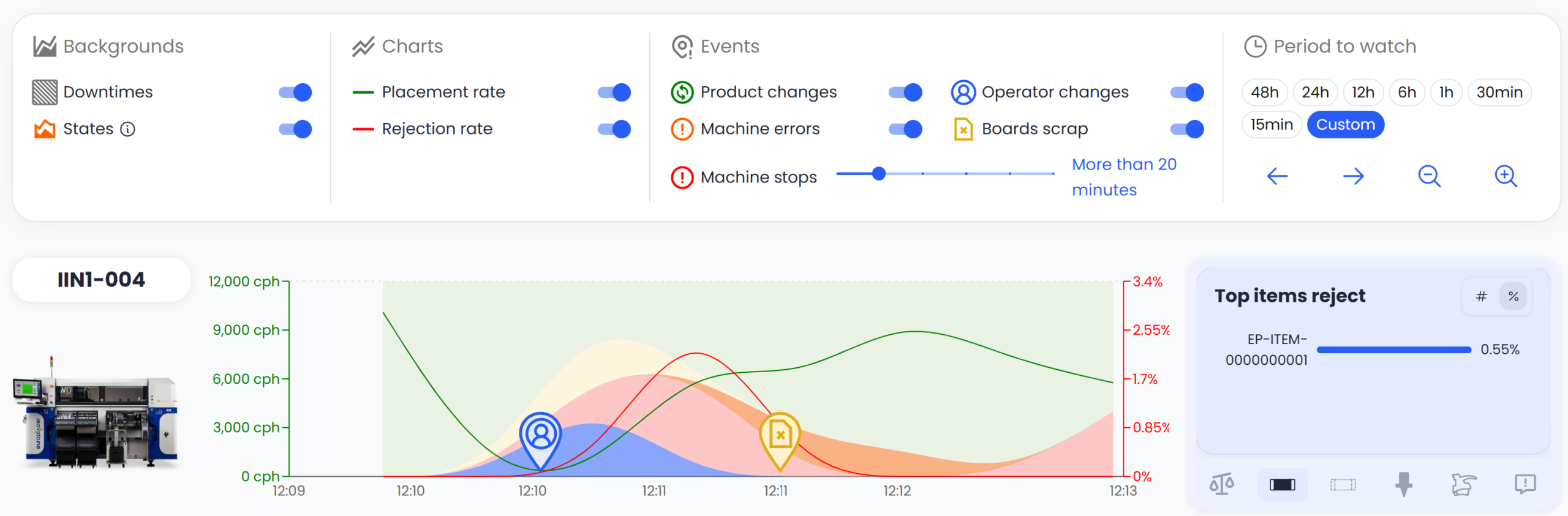

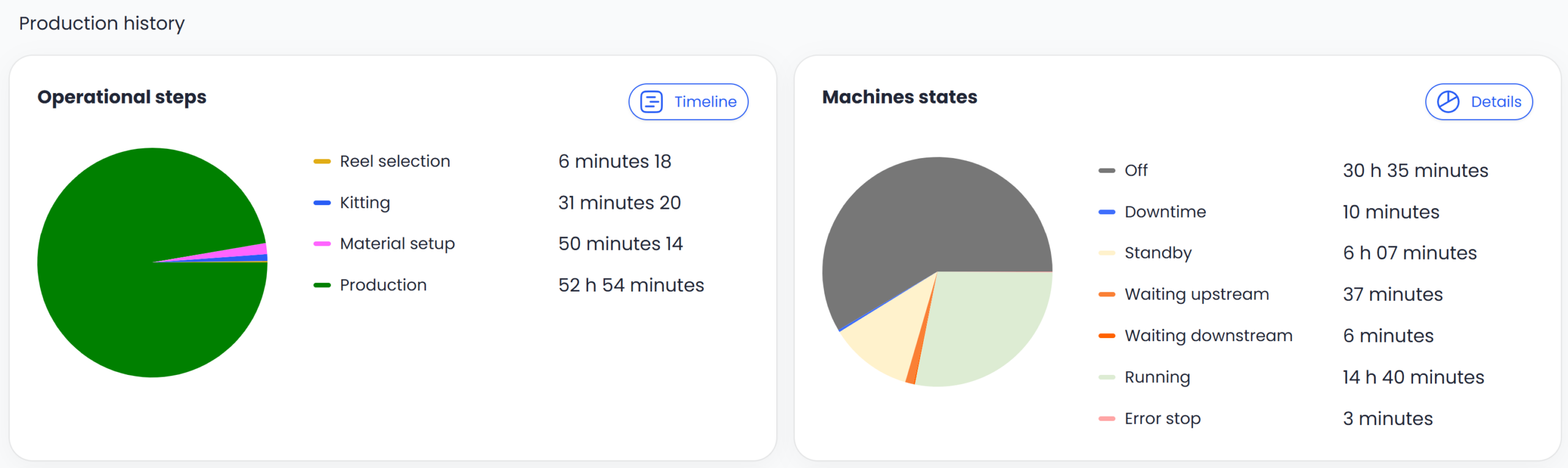

The Line Analysis view helps teams understand what happened on the production line over time, why it happened, and with what impact. By combining performance indicators with real production context, it provides a clear and objective view of line behavior.

This contextual analysis makes it easier to identify trends, deviations, and recurring issues. It supports informed decision-making and continuous improvement, helping teams increase productivity.

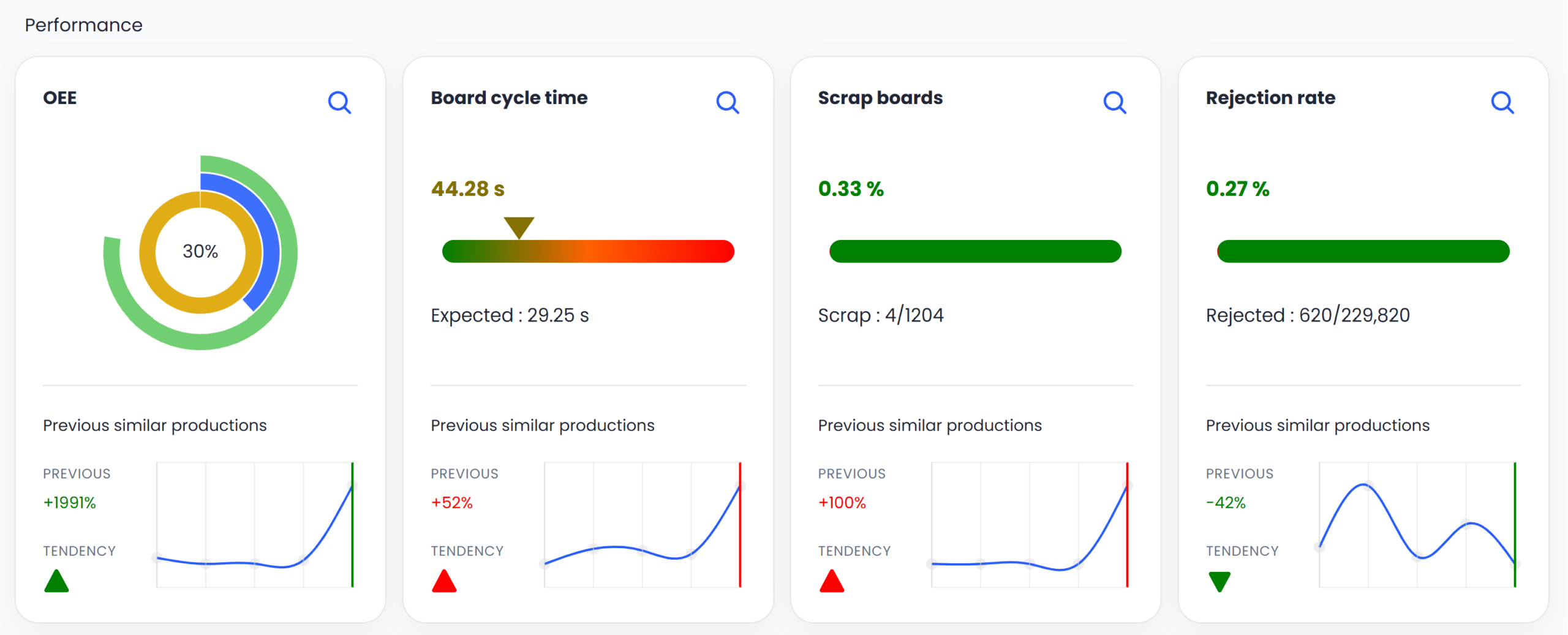

Performance adapted to your environment

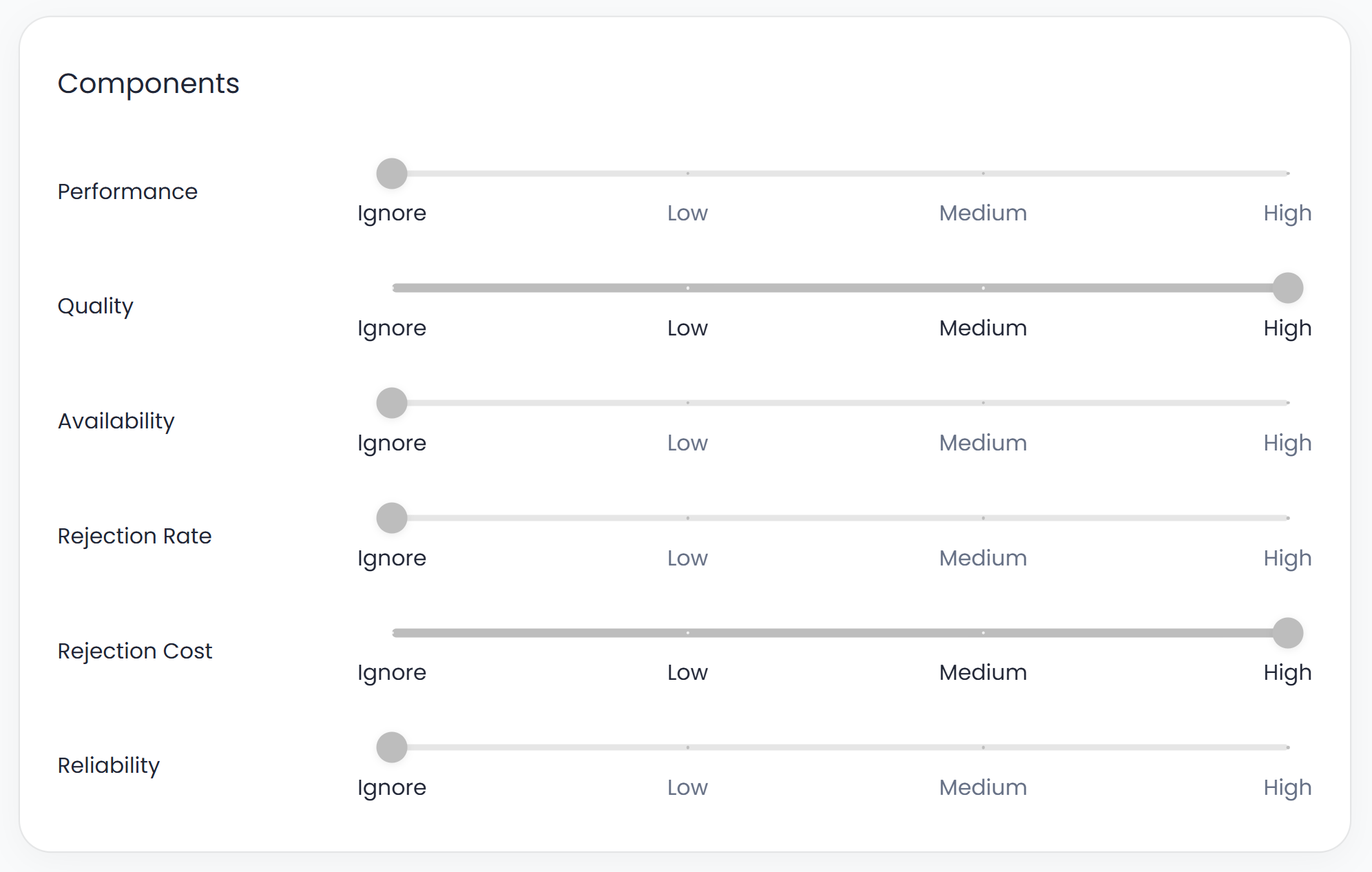

The HMP (High Mix Performance) indicator addresses the limitations of traditional KPIs in high-mix environments, where product variability and frequent changeovers make standard metrics less representative.

Fully customizable, it allows you to define key performance criteria such as quality, speed, cost of rejects, or equipment reliability, ensuring alignment with your

operational priorities.

Calculated over short time windows, HMP drives immediate action and becomes a simple, practical lever for monitoring and continuously improving performance.

Performance adapted to your environment

The HMP (High Mix Performance) indicator addresses the limitations of traditional KPIs in high-mix environments, where product variability and frequent changeovers make standard metrics less representative.

Fully customizable, it allows you to define key performance criteria such as quality, speed, cost of rejects, or equipment reliability, ensuring alignment with your

operational priorities.

Calculated over short time windows, HMP drives immediate action and becomes a simple, practical lever for monitoring and continuously improving performance.

Production Report

Post-Production Analysis & Performance Management

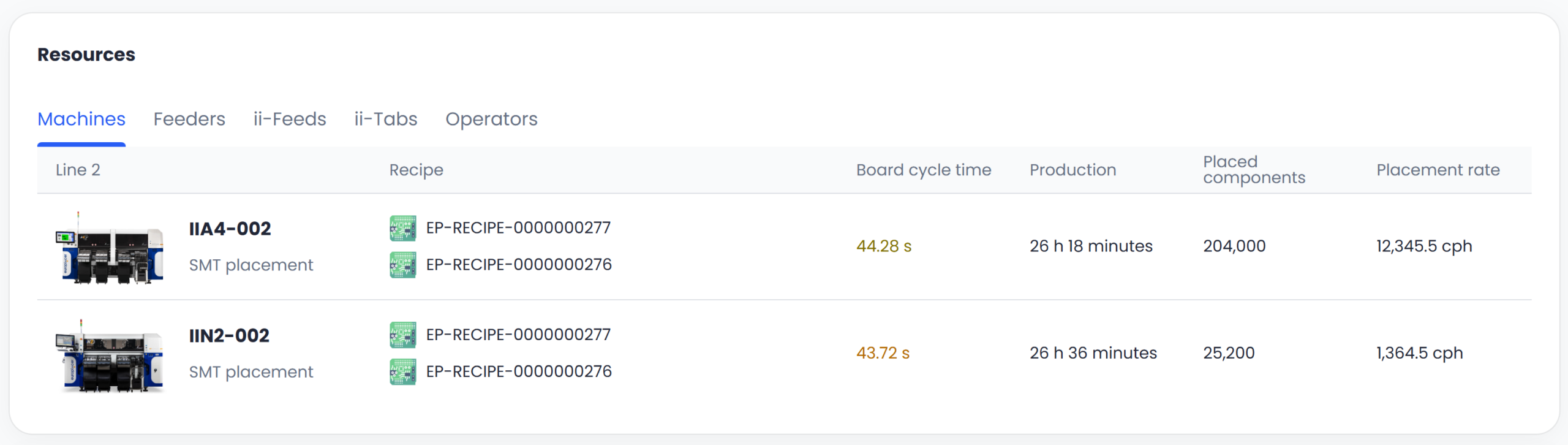

The Production Report module provides an automated and structured analysis of each completed work order, delivering a clear and actionable view of production performance. All key information—duration, output, KPIs, events, and operator notes—is consolidated into a single report. Beyond global indicators, the report analyzes resources, consumables, scrap, and rejections with high level of detail.

By including cost-based insights and comparisons with similar productions, EPiiCENTRE helps teams identify gaps, learn from past runs, and define targeted actions to continuously improve future production.

- Automatically generated reports with no manual compilation

- Clear and objective view of each work order

- Detailed analysis of resources, consumables, and costs

- Comparison with similar productions to accelerate improvement

- Practical decision support and continuous improvement enablement

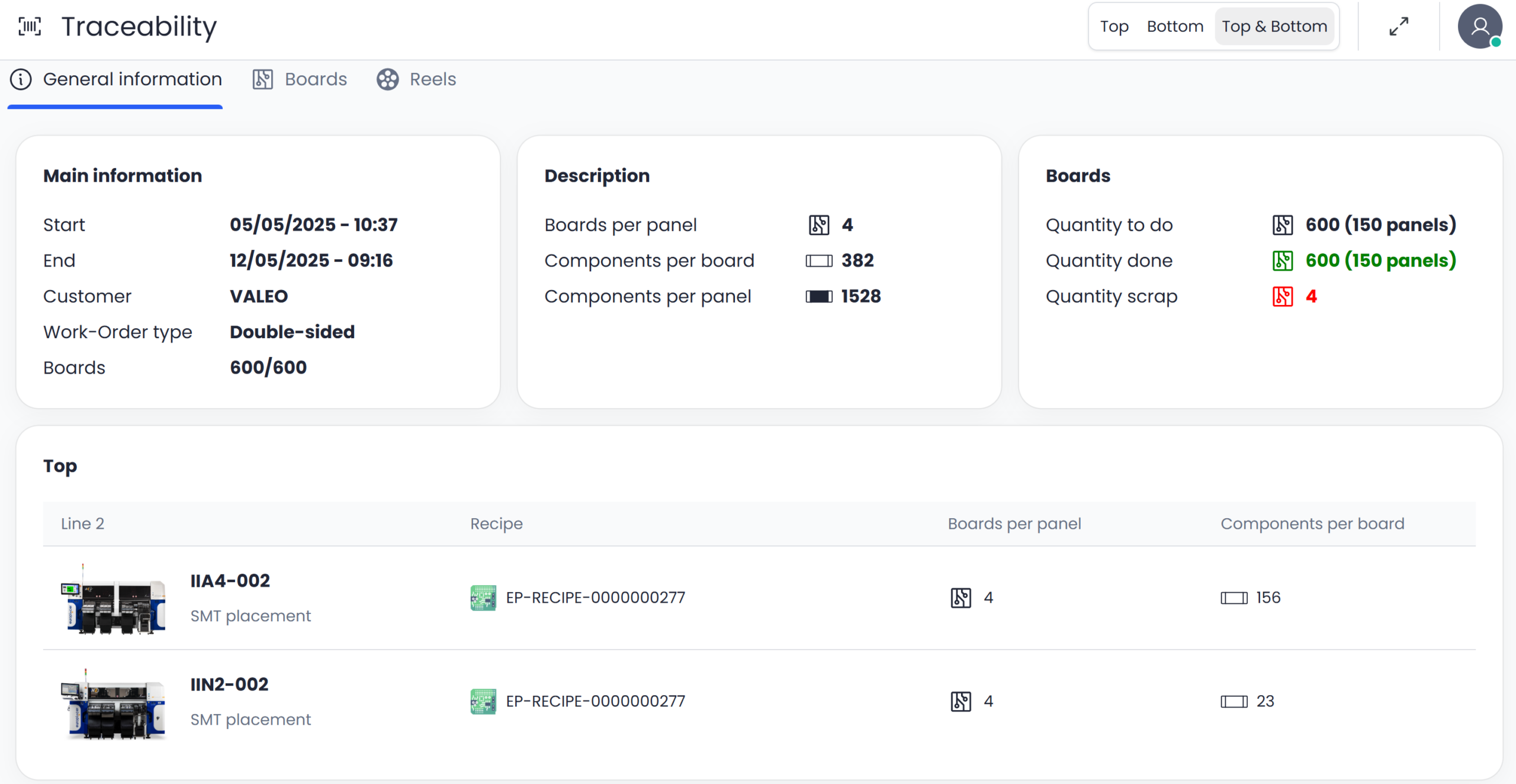

Traceability

Gain unparalleled insight into every stage of your product’s lifecycle, from raw materials to finished goods.

- Complete Product Tracking: Follow individual products through every assembly.

- Work order Traceability: Isolate and identify specific production for swift analysis or recalls.

- Component Genealogy: Access a detailed history of every single component integrated into a product.

- Quality Audit Trails: Review comprehensive logs of all events and their outcomes.

This robust traceability ensures compliance, enhances quality control, and facilitates rapid issue resolution.

Find out how EPiiCENTRE can revolutionize your production. Request a call back using the form below.