Best In Class For Prototyping

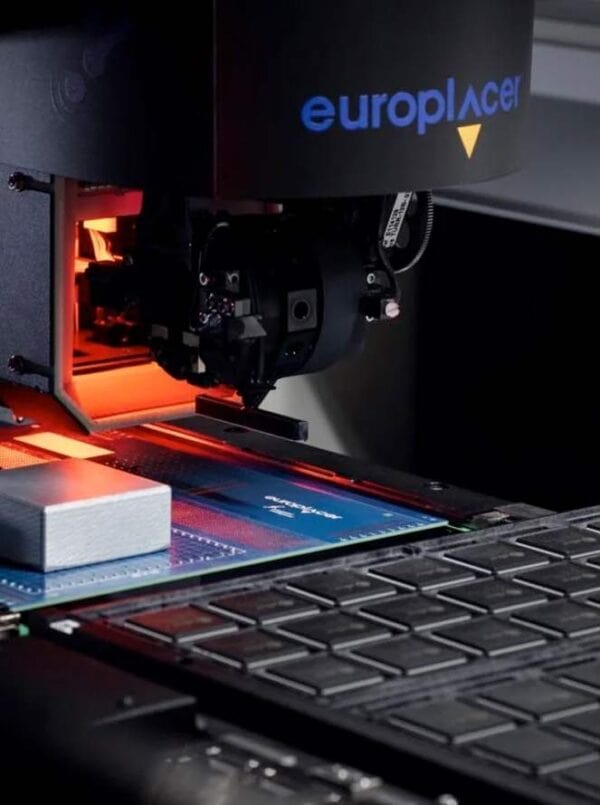

With the ii-N1 in your production line, you never have to say no. The platform is built on Europlacer’s unique multi core processing technology which is designed to deal with all surface mount assembly demands, with no compromise. With the introduction of the elegant ii-N1 machine, you will increase productivity and deliver premium performance for any assembly application.

As you might expect from Europlacer, the SMT placement equipment iineo is a single elegant structure capable of almost unlimited configurations. The capability that comes as standard within the machine is however the most important aspect of this platform:

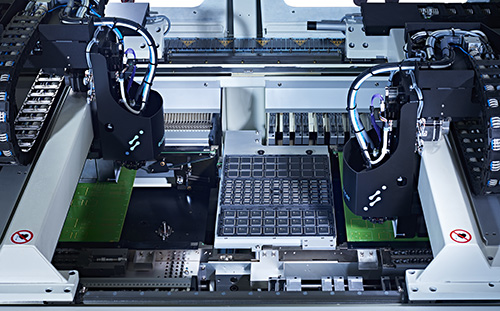

On most of pick and place machines, the heads can only place a specific range of components. It certainly just makes life complicated. As a result you can’t effectively balance that single machine, let alone a complete line. That’s why the SMT placement machine iineo has genuine line balancing capabilities. All heads and all nozzle positions capable of placing the full range of components. Above all, you don’t have to compromise on feeder positions or throughput speed, production can run as efficiently as is possible.

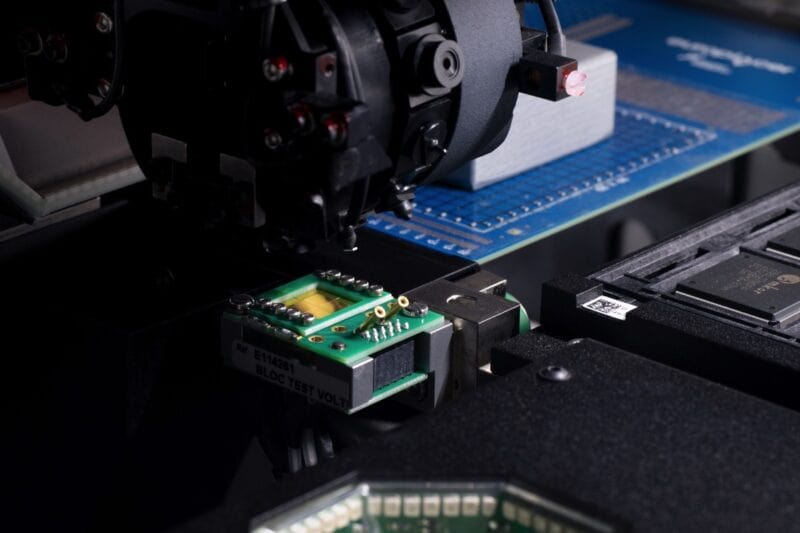

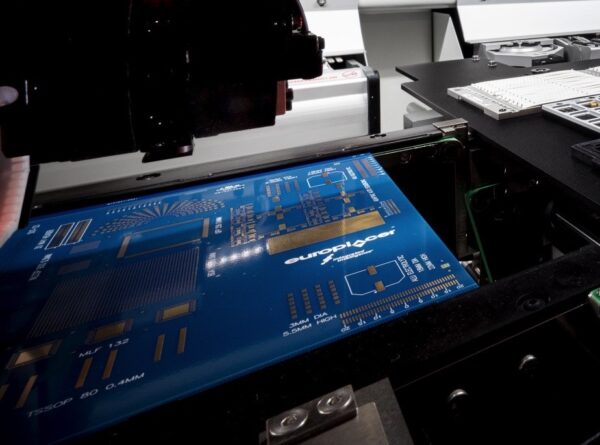

Firstly iineo is fitted with linear motors and digital cameras. In addition, it utilises Europlacer’s unique and proven core features such as Integrated IntelligenceTM , intelligent feeders, smart nozzles and 3DPS. 3DPS provides guaranteed closed loop control of pick and placement forces for all components. Importantly, iineo is able to produce very large boards, as it is capable of being configured to manage 1610mm x 600mm size substrates.

The latest intelligent technology to ensure component identification, correct pick-up, inventory management and avoid manufacturing errors.

As the original creator of intelligent feeders, you can be sure you are getting the best.

We design our platforms around the feeders to deliver an incomparably integrated pick and place solution.

| ii-N1 | |

| Component Range | 03015m to 50mm x 50mm |

| (With fixed camera) | 99mm x 99mm* |

| Max Component Height | 34mm (31mm with 12 nozzles) |

| Feeder: Tapes | 4mm to 104mm |

| Feeder: Capacity | 264 positions x 8mm |

| Feeder: Internal | 10 x Matrix trays |

| Placement Heads | 1 x 8 or 12 nozzle Tornado head |

| Max PCB Size | 1610mm x 600mm *** |

| Max Placement Rate | 15,390cph** |

* With Tornado 8 nozzles with Matrix Tray distributor with less shims or auto tray loader with specific tray support.

** With 12 nozzle position – Optimum test conditions in factory.

*** Option available only with special conveyor for very long and wide boards, standard conveyor is 700x460mm.

Machine

- Fixed upward-looking camera for larger and very fine pitch components

Software and Programming

- Offline preparation

- Stock Management

- Full Traceability

- PROMON Software

Feeders

- Barcode feeders

- Bulk feeders

- Ball feeders for BGAs

- Flux feeder & PoP processing

- Tray sequencer

Find out what the inneo ii-N1 can do for your production line. Complete the form below to request a call back.